Display Options Available

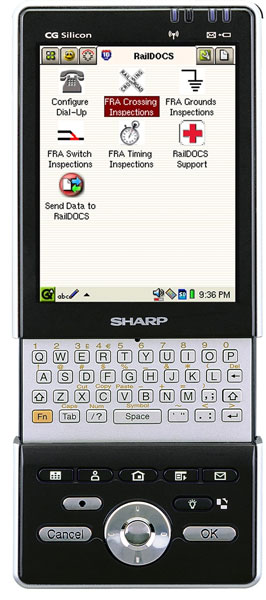

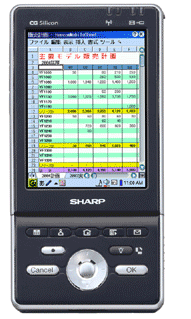

Below are two pictures of the new Sharp Zaurus SL-6000. The image on the left is grainy because it has been resized; click on the image for a full-size view of the Zaurus.

There are too many options to list them individually here, so this site will only discuss the choices the Galileo developers have standardized on. It is worth noting that there is no requirement for all of the displays to be identical in the same system. It might be appropriate to install several small, interchangeable panels for attitude, navigation, and engine monitoring, while installing one larger unit for GPS moving map functionality. The same data is available to all display modules, so they all have the opportunity to use that data for their own purposes.

There are several benefits to this approach, the most important of which are straightforward construction and testing for individual components, and increased reliability - the failure of one sensor module or display does not imply the failure of the entire system. In "all-in-one" commercial units, power supply or similar component failures could take down the entire system.

Displays

There are a variety of display options available, and selecting among them invariably involves some trade-off. The products are discussed in more detail in the Displays section, but in summary these options include:

- PDAs

- These devices include nearly all of the functionality of an ideal display in an integrated package - compact construction, multiple interface options, off-the-shelf availability, touch screens, etc. Their trade-offs include poor sunlight readability for most devices, poor night-time dimming ranges for the sunlight-readable options, and limited screen size and resolution options.

- Laptops

- Laptops offer significant functionality (high CPU speeds and large storage devices) but their size and weight are undesirable for most GA aircraft. They also generally suffer from poor sunlight readability, poor user interfaces for flying operations (keyboards and mice are not appropriate pilot interfaces), and high cost. Finally, since their screens are generally permanently attached and difficult to remove, they can be hard to install.

- Embedded Computers with Separate Displays

- Embedded systems solve some of the problems with laptops, namely the option to use an external display. Sunlight-readable options are difficult to find, but this situation is at least improving as these devices are deployed more in automotive environments. Unfortunately, the better embedded systems actually cost more than laptops because this is a low-volume market.

- Tablet PCs and Other Hybrids

- Tablet PCs offer the "best" of both worlds between embedded systems and laptops. The screens are integrated but point outward, so installation is less awkward, and they include touch screens for user interaction. There are more sunlight-readable options available as well. They're still not perfect - "sunlight readable" is a pretty loose term, and they're still on the large side. They're also some of the most expensive options in the group, especially for "ideal" units with modern screens.

- Custom Hardware

- It is possible to create custom display modules using OEM LCD screens and microcontrollers. This is the route Jeff Wilson is taking (see the project home page for a link to his site). Custom designs offer the greatest flexibility in LCD panel selection as well as complete control over every line of code, making it much easier to guarantee system behaviors. However, this method also requires the most electronic design and construction knowledge and experience, and is beyond the soldering and construction skills of most homebuilders. As such, the Galileo designers will make every attempt to either be compatible with or produce data conversion layers to allow the use of these panels, but will not design around them by default.

Sensor Modules

The greatest usage of the distributed concept will be in sensor modules. That is, the collection of air pressures and fuel levels will be peformed by different modules sited near the data they collect. This greatly simplifies wiring, as the entire system uses only a single 4-conductor cable (power, ground, CAN-high, and CAN-lo).

In fact, it is theoretically possible to replace most of an aircraft's power wiring harness as well, by creating a module that controls one or more power relays, with one of these modules installed near each controlled device. Galileo's developers have discussed such options, and for the moment deferred this design as it introduces much more risk into the system. It is unclear whether the weight and wiring complexity reductions would be enough to offset this risk.

Individual modules will be low-cost ($20-$40 on average, $100-$200 for the magnetometer and gyro modules) and generally easy to construct. The only concession made by designers was to avoid focusing on home etching. Galileo PCBs have vias and reverse-side traces. It is not impossible to etch these at home, using jumpers and inserts, but support for this effort will not be explicitly provided. Sorry; the small size of most of these boards does require a higher level of integration and miniaturization, and this would not be possible with traditional perfboard- or simple-PCB construction.

Given the availability of low-cost PCB production services like Olimex there's just no margin in this anymore. Gerber files for all modules are provided; if you want a PCB you can simply send them to any PCB house. If donations are sufficient to cover overhead costs, the developers will produce PCBs in bulk and provide them (and possible pre-built devices) to builders at a lower cost than buying single units.